Our world class manufacturing site is unrivalled for its expansive footprint in both digital and conventional capabilities.

The knowledge and harmonisation of both technologies under the same roof provides our customers with the perfect label solution every time.

Our closed colour loop management program ensures we match to exacting colour standards and achieve accurate repeatability, meeting all retail and ISO standards.

TAKING A CONVENTIONAL APPROACH

FLEXO UV

Our Mark Andy conventional UV presses play a vital part in the make-up of our manufacturing portfolio as we continue to invest in this technology.

It’s an evolving and unrivalled conventional print process for medium to long run requirements.

The versatility from our conventional presses is extensive; we can print on a wide range of substrate types, complimented with a multitude of in-line embellishments and finishing solutions.

All of our presses are profiled to point to one managed standard, ISO Coated V2 (Fogra 39L/47L).

PMS spot colours are verified to a Delta E of <2 against digital pantone plus or supplied CFX data.

Complementing our colour management programme we have the very latest in CTP technology with Full HD, realising the optimum in quality from UV Flexo.

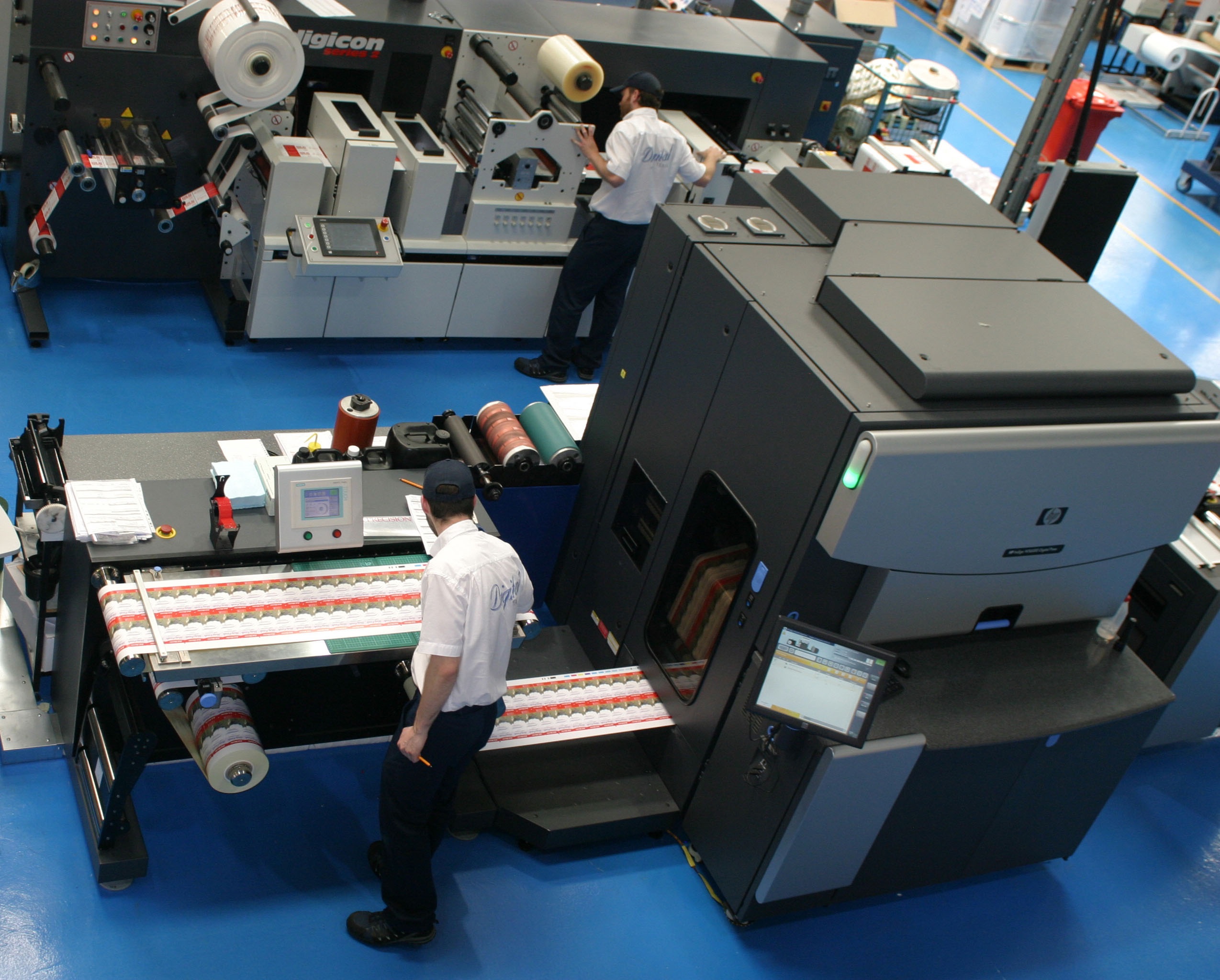

THE ULTIMATE IN DIGITAL PERFORMANCE

Our digital portfolio has two complimentary technologies, HP Indigo and Bobst Inkjet that cover every aspect of your label requirements.

These technologies provide the perfect solution for short to medium and multi-run sort requirements.

HP INDIGO

Our customers receive exceptional quality, registration and colour consistency from our HP digital presses.

They have an extensive colour gamut that reaches up to 97% of PANTONE® colours using CMYK, orange, violet, green and white.

In addition HP’s ink portfolio also includes metallic silver, fluorescents and security UV inks.

BOBST INKJET

Our Bobst Inkjet provides excellent opacity and is the perfect solution for stand out colours, particularly when using clear materials.

Printing up to 6 colours with a 73% opacity white the end label results have a screen like appearance to them that are often seen on brands in the personal care market.

The inks have great light fastness, scuff resistance and are extremely robust.

FINISHING AHEAD OF THE REST

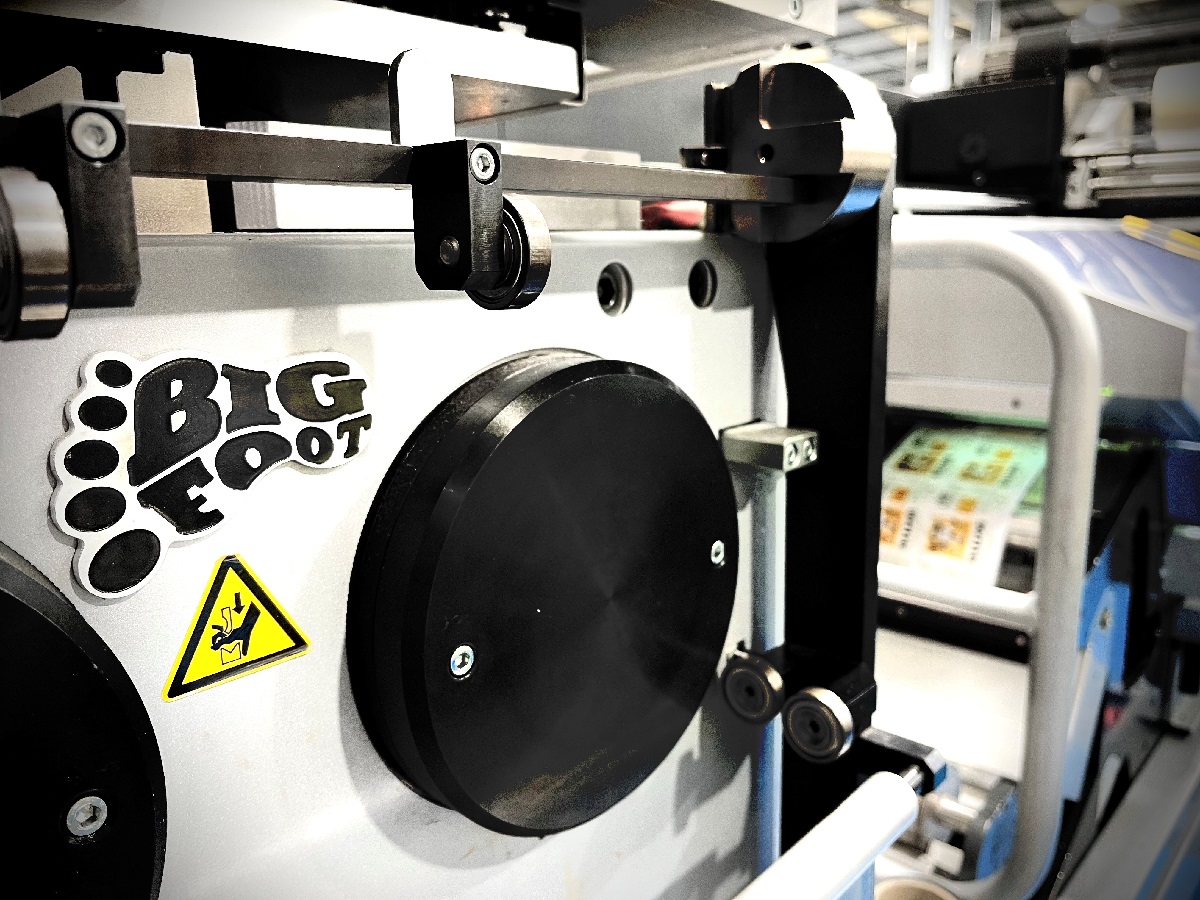

ABG DIGICON

Our digital presses are complimented by our portfolio of digicons from market leaders ABG international, enabling us to realise stunning decorative finishes on our labels.

From our five Digicon finishing machines we are able to produce foil, embossing, screen, spot PMS colours, decorative varnishes and peel and read constructions.

Our two ABG big foot modules can apply 50 tons of pressure, with the capability to run multiple foils and embossing, with tactile screen as an additional option – all in one pass.